Benefits of Omya solutions for engineering polymers

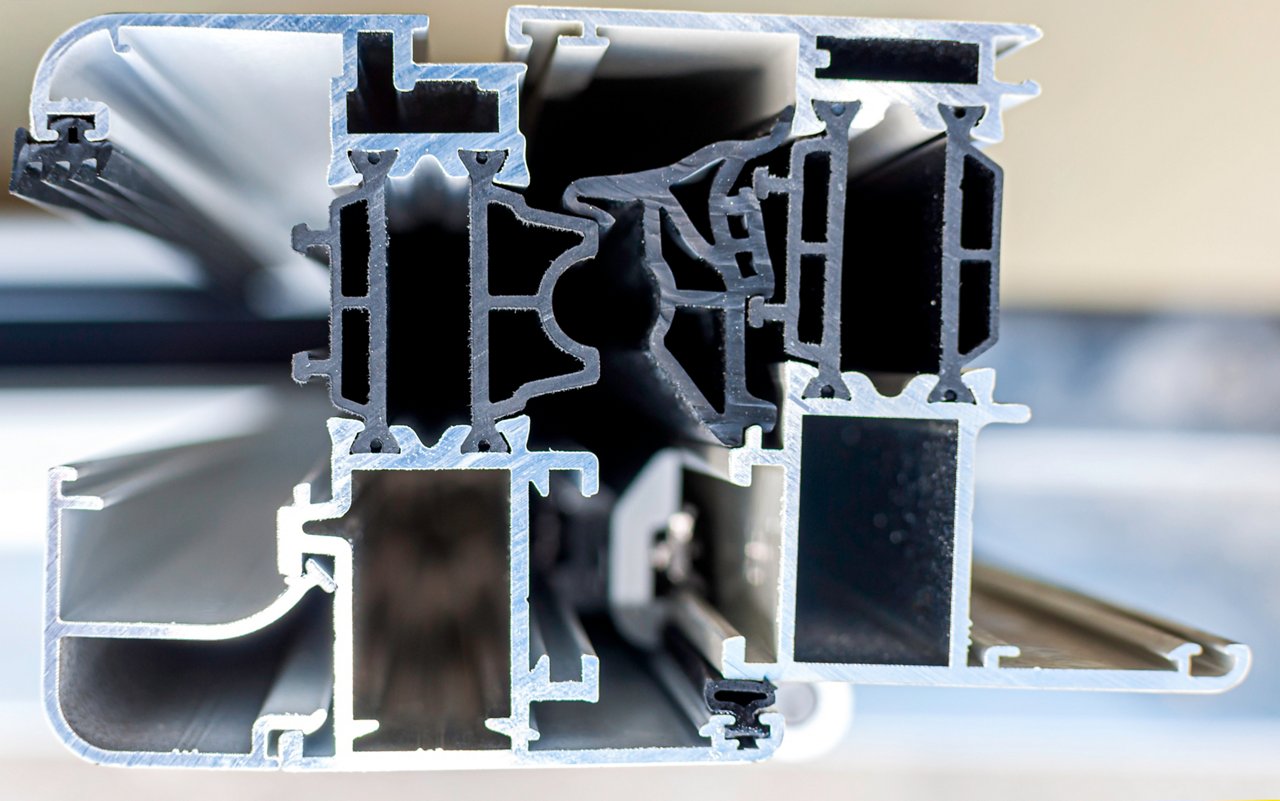

- Improved ductility in PA and PC

- Partial glass fiber and mineral replacement

- Partial pigment and polymer replacement

- Reduced Polycarbonate extrusion degradation

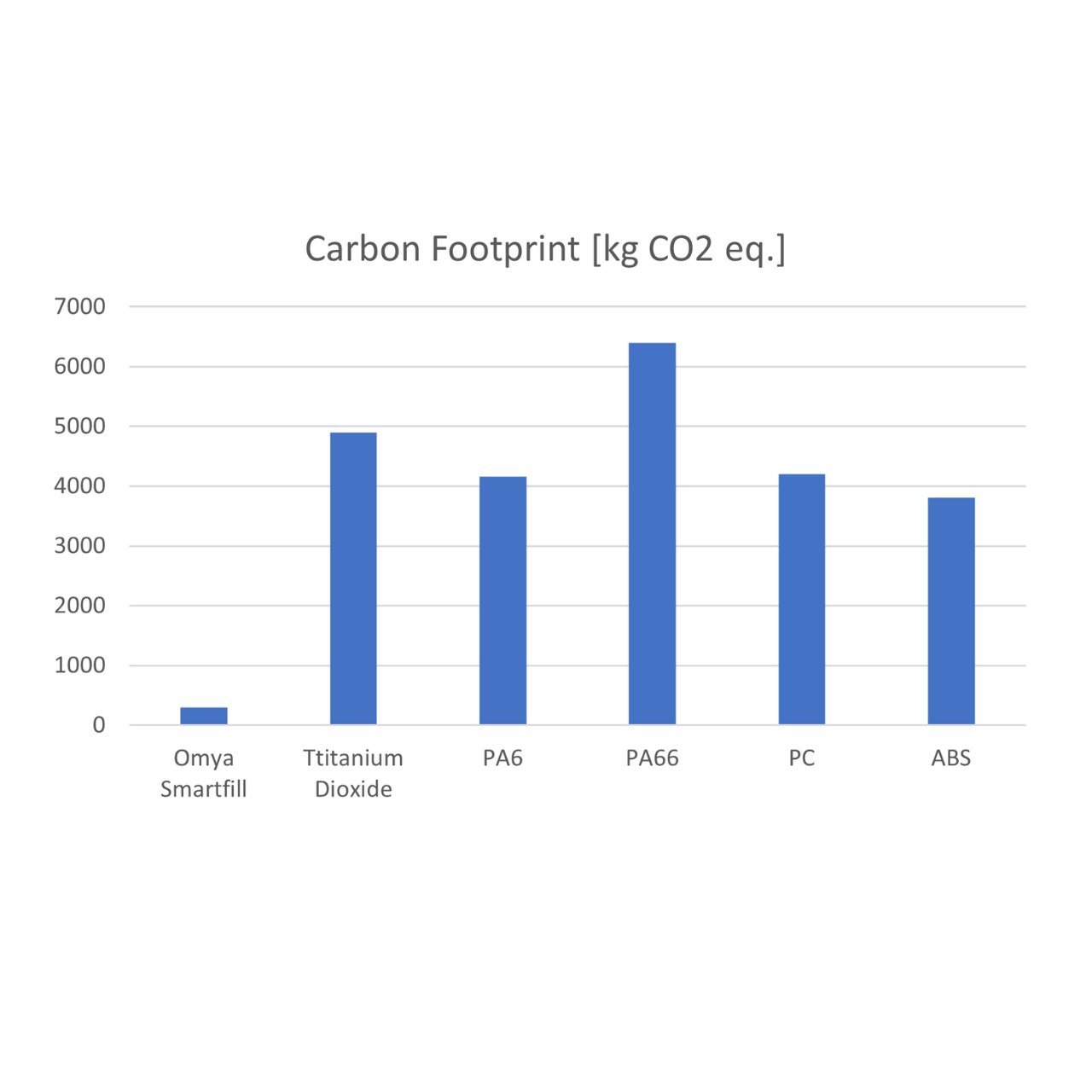

- Lower carbon footprint

- Reduced formulation cost

?qlt=85&ts=1705067366288&dpr=off)